Wszystkie produkty

-

Cewka z taśmy aluminiowej

-

Cewka aluminiowa powlekana kolorem

-

Rolka z folii aluminiowej

-

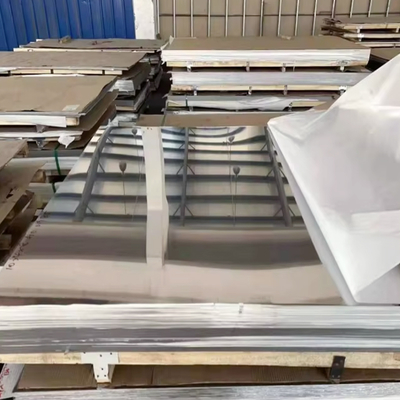

Aluminiowa płyta

-

Aluminiowy krążek

-

folia poliestrowa laminowana z folii aluminium

-

Płyta aluminiowa w kratkę

-

Blacha aluminiowa diamentowa

-

Tłoczona blacha aluminiowa

-

Anodowana blacha aluminiowa

-

Lustrzana blacha aluminiowa

-

Pojemnik z folii aluminiowej

-

Pudełko na lunch z folii aluminiowej

-

Grill jednorazowy

-

Jaskółka oknówkaKiedy po raz pierwszy współpracowaliśmy z Yongsheng Aluminium, okazało się to bardzo łatwe, ponieważ czas dostawy towarów był bardzo szybki, a kierownik firmy był również bardzo profesjonalny.

Jaskółka oknówkaKiedy po raz pierwszy współpracowaliśmy z Yongsheng Aluminium, okazało się to bardzo łatwe, ponieważ czas dostawy towarów był bardzo szybki, a kierownik firmy był również bardzo profesjonalny. -

Alice SuNasza firma i Yongsheng Aluminium współpracują od prawie trzech lat.

Alice SuNasza firma i Yongsheng Aluminium współpracują od prawie trzech lat. -

ZoeyKupujemy koła aluminiowe od Yongsheng Aluminium i wysyłamy je do Ghany.

ZoeyKupujemy koła aluminiowe od Yongsheng Aluminium i wysyłamy je do Ghany. -

Amin MazlumKupiliśmy łącznie prawie 500 ton tłoczonych kolorowych cewek aluminiowych od Yongsheng Aluminium.

Amin MazlumKupiliśmy łącznie prawie 500 ton tłoczonych kolorowych cewek aluminiowych od Yongsheng Aluminium.

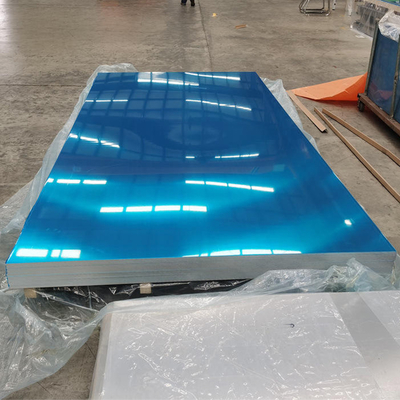

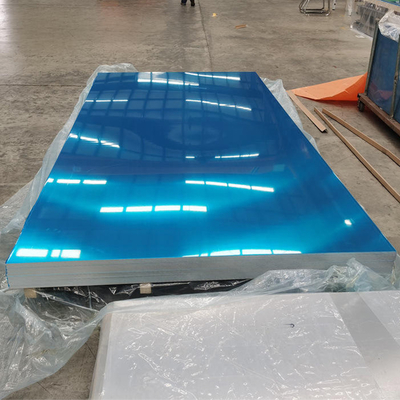

1100 1060 Aluminum Sheet 0.5mm Thickness for Food Packaging/Electronic Heat Dissipation

| Miejsce pochodzenia | Prowincja Henan, Chiny |

|---|---|

| Nazwa handlowa | YONGSHENG |

| Orzecznictwo | ISO, RoHS |

| Numer modelu | 1000 serii 3000 5000 |

| Minimalne zamówienie | 2 tony |

| Cena | 3050-3250 USD/Ton |

| Szczegóły pakowania | Standardowe opakowanie na morze |

| Czas dostawy | 7-25 dni po potwierdzeniu zamówienia |

| Zasady płatności | L/C, D/A, D/P, T/T |

| Możliwość Supply | 5000 ton miesięcznie |

Skontaktuj się ze mną, aby uzyskać bezpłatne próbki i kupony.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

W razie jakichkolwiek wątpliwości zapewniamy całodobową pomoc online.

xSzczegóły Produktu

| Słowo kluczowe | Arkusz aluminiowy | Tworzywo | Metal aluminiowy |

|---|---|---|---|

| Hartować | O-H112 | Szerokość | 10-2000 mm |

| Grubość | 0,15-200 mm dostosowane | Kształt | Płaska płyta |

| Obróbka powierzchniowa | Wykończenie młyna | Usługa przetwarzania | Zginanie, oddzielenie, spawanie, uderzenie, cięcie |

| Port | Qingdao, Szanghaj, Tianjin | Próbka | Bezpłatny |

| Podkreślić | 0.5mm aluminum sheet for food packaging,1060 aluminum plate for heat dissipation,1100 aluminum sheet with 0.5mm thickness |

||

opis produktu

1100 1060 Arkusz aluminiowy 0,5 mm grubość

Szczególnie zaprojektowana do pakowania żywności i elektronicznego rozpraszania ciepła, blacha aluminiowa o grubości 0,5 mm zapewniająca optymalne osiągi.

Przegląd serii stopów aluminium

| Seria stopów | Główne cechy | Typowe zastosowania |

|---|---|---|

| Seria 1000 | Płyty z czystego aluminium - miękka konsystencja, niezwykle odporna na korozję, doskonała przewodność elektryczna/cieplna, niska wytrzymałość, łatwa w obróbce |

|

| Seria 2000 | Płytka stopowa Al-Cu - Wysoka wytrzymałość, odporność na wysokie temperatury, wymaga obróbki powierzchniowej w celu ochrony przed korozją |

|

| Seria 3000 | Płytka ze stopu Al-Mn - średnia wytrzymałość, doskonała odporność na korozję, dobra plastyczność, łatwe spawanie |

|

| Seria 4000 | Płytka ze stopu Al-Si - niska temperatura topnienia, odporna na zużycie, stosowana głównie w odlewach |

|

| Seria 5000 | Płytka stopowa Al-Mg - Wysoka wytrzymałość, niezwykle silna odporność na korozję, doskonała wydajność w niskich temperaturach, łatwo kształtowana |

|

| Seria 6000 | Płytka stopowa Al-Mg-Si - wzmocniona przez obróbkę termiczną, średnia wytrzymałość, doskonała odporność na korozję, wyższa obróbczność |

|

| Seria 7000 | Niezwykle wysoka wytrzymałość, wymaga ochrony przed korozją, wysoka cena |

|

Zalety techniczne i procesów

Dojrzałe technologie stopienia i odlewania:Nasza fabryka utrzymuje precyzyjną kontrolę temperatury dla różnych materiałów płyt aluminiowych, w tym serii 1 (czysty aluminium), serii 3 (stop aluminiowo-manganowy) i serii 5 (stop aluminiowo-magnezowy).Temperatura topnienia czystego aluminium jest precyzyjnie kontrolowana w granicach 660-700°C. Zaawansowane procesy odgazowania i usuwania łupów minimalizują wady wewnętrzne,o właściwościach mechanicznych wahających się w zakresie ± 5% - znacznie lepsze niż średnia branżowa wynosząca ± 8%.

Wykonanie obróbki powierzchni i walcowania o wysokiej precyzji:Wyposażone w modernizowane czterorolkowe odwracalne walcowanie na zimno, zdolne do obróbki płyt aluminiowych o grubości od 0,1 mm do 10 mm. Tolerancja grubości wynosi ±0,01 mm,spełniające rygorystyczne wymagania dotyczące elektroniki i opakowańPełna gama metod obróbki powierzchniowej, w tym anodowanie, powłoka elektrografowana i powłoka foliowa dostępne z niestandardowymi wykończeniami (lustrzane, matowe lub szczotkowane).Powierzchnie powłoki przechodzą badanie na rozpylanie soli (neutralne badanie na rozpylanie soli ≥ 500 godzin).

Szybka reakcja procesu:Our established "process parameter database" enables quick matching of exclusive production processes for specialized applications including marine-grade 5 series aluminum plates and automotive 3 series lightweight aluminum platesCykl potwierdzenia zamówienia jest o 30% krótszy niż średnia w branży.

Zarządzanie kontrolą jakości

Dokładny wybór surowca:Wykorzystujemy wyłącznie sztabki aluminium o wysokiej czystości spełniające normy GB/T3190 (Chiny) lub ASTMB209 (USA) o zawartości aluminium ≥ 99,7%.Każda partia poddawana jest badaniom składu spektrometru w celu zapobiegania problemom z wydajnością z powodu zanieczyszczeń.

Monitoring produkcji w czasie rzeczywistym:Kluczowe procesy (topienie, walcowanie, wygrzewanie) są wyposażone w urządzenia wykrywające w trybie online z monitorowaniem składu i temperatury w czasie rzeczywistym.Mierniki grubości laserowej kontrolują precyzję walcowania, podczas gdy termopar monitorować jednolitość temperatury piecaDane dotyczące produkcji są rejestrowane co 10 minut w celu zapewnienia pełnej identyfikowalności.

Kompleksowa kontrola gotowego produktu:Czteropoziomowy protokół inspekcji obejmujący wygląd, wymiary, wydajność i odporność na warunki pogodowe.Mikrometry i kalitry vernier do kontroli wymiarów (częstość pobierania próbek ≥ 5%)., uniwersalne badania właściwości mechanicznych materiału oraz badania cyklowe w wysokich/niskich temperaturach (-40°C do 80°C, 50 cykli) dla zastosowań zewnętrznych.Produkty niezgodne z wymaganiami otrzymują 100% przeróbki, przy czym wskaźnik przejścia fabrycznego stale przekracza 99%.0,8%.

Szczegóły produktu

Zastosowanie produktu

Polecane produkty